The solvent used in the G1S Mark-II is immobile or stagnant, which significantly reduces the amount of water required to filter the particles.

Our Products & Services

Our Flagship Product

At Generation One Saver , we specialize in advanced air pollution control systems designed to capture and convert harmful industrial emissions into breathable oxygen. Our cutting-edge technology analyzes the content of emissions and utilizes a unique blend of plants and solvents to absorb pollutants effectively.

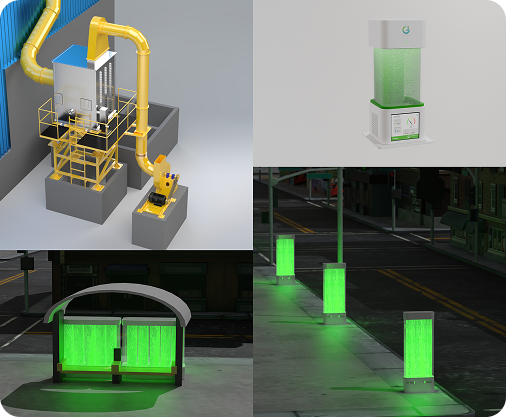

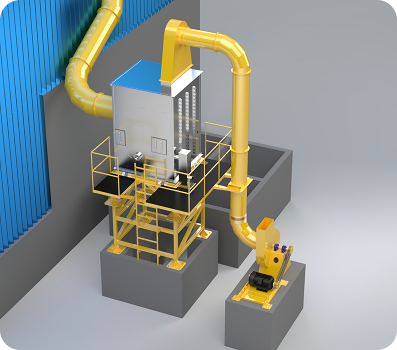

Industrial Air Pollution Control System

The G1S Mark II is a newly developed air pollution control system engineered to capture and neutralize industrial pollutants at the source. Designed for performance, durability, and efficiency, it provides reliable emission control for demanding industrial environments.

Advantages of G1S Mark-II

Converting Phase

It purify the air with help micro algae and it can reduce the co2 levels considerably higher than any indoor plants

How does G1S Mark-II

01

Suction and Capture

The process begins with the suction blower, which draws in polluted air directly from the emission source. This ensures that no pollutants are left unaddressed.

02

Zig-Zag Pathway

Once inside the system, the polluted air is forced through a uniquely designed zig-zag pathway. This intricate pathway maximizes the contact time between the pollutants and the solvent, enhancing the overall efficiency of the system.

03

Solvent Interaction

As the polluted air navigates the zig-zag path, it comes into direct contact with a specialized solvent. This solvent is tailored to react with and neutralize the specific pollutants present in the smoke.

04

Particulate Settling

The zig-zag design not only increases contact time but also creates conditions that cause most particulate matter to settle out of the air stream. Heavier particles drop out of the airflow, collecting in designated areas for easy disposal.

05

Clean Air Release

After passing through the solvent interaction and particulate settling stages, the cleaned air is released from the system. Only non-toxic, non-harmful particles are allowed to escape, ensuring that the output air is significantly cleaner and safer for the environment.

Our Products

1. Zig-Zag Chamber

An industrial-grade emission control unit designed to capture and reduce particulate matter and pollutants through an optimized zig-zag airflow pathway. Suitable for manufacturing units, power plants, and heavy industrial facilities, it ensures high efficiency, low maintenance, and continuous operation.

Achievable Flow Rates

1500 CFM - 4500 CFM

Blower Capacity

10 HP - 50 HP

Total Pressure Drop

2000 Pa

Efficiency of

Controlling Pollutants

96% - 98%

2. Tubular Photobioreactor (PBR)

A sustainable carbon management solution that uses high-yield microalgae to capture industrial CO₂ emissions and convert them into valuable biomass. Designed for integration downstream of emission control systems, it supports carbon sequestration and circular economy initiatives.

CO₂ Sequestration Rate

1500 CFM - 4500 CFM

Biomass Productivity

0.5 - 1.2 g/L/day

Tube Diameter

Standard 4- Inch (100mm)

Operational Mode

Continuous / Semi-Continuous

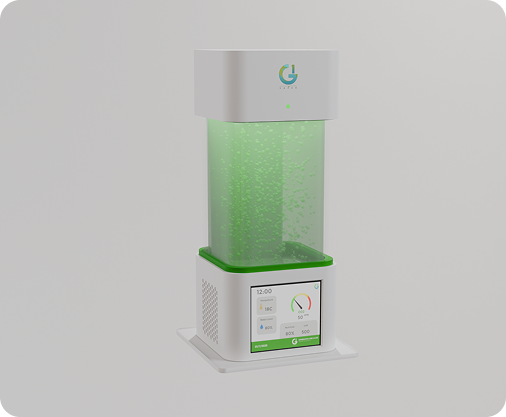

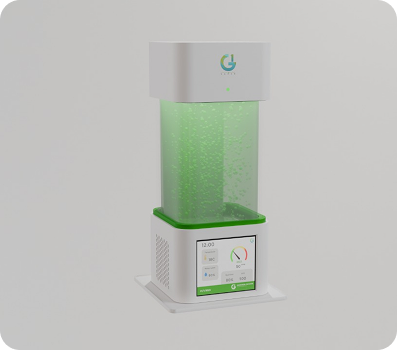

3. Indoor Photo-Bioreactor

A sustainable carbon management solution that uses high-yield microalgae to capture industrial CO₂ emissions and convert them into valuable biomass. Designed for integration downstream of emission control systems, it supports carbon sequestration and circular economy initiatives.

Coverage Area

250 - 500 sq. ft.

Oxygen Output

10-15 Plants

Power Input

12V DC

Maintenance

Monthly Top-up

Other Products

4. Precision Air Quality Monitoring

Advanced monitoring systems designed to track indoor air quality parameters in real time. Ideal for offices, schools, and commercial spaces, these systems help prevent poor air conditions and support healthier indoor environments.

PM (1–10)

CO₂

HCHO

Temperature, Humidity

5. Precision Gas Monitoring

Industrial-grade gas monitoring solutions engineered for harsh environments, including factories, stacks, and process areas. These systems provide real-time alerts to help industries maintain compliance and avoid regulatory penalties.